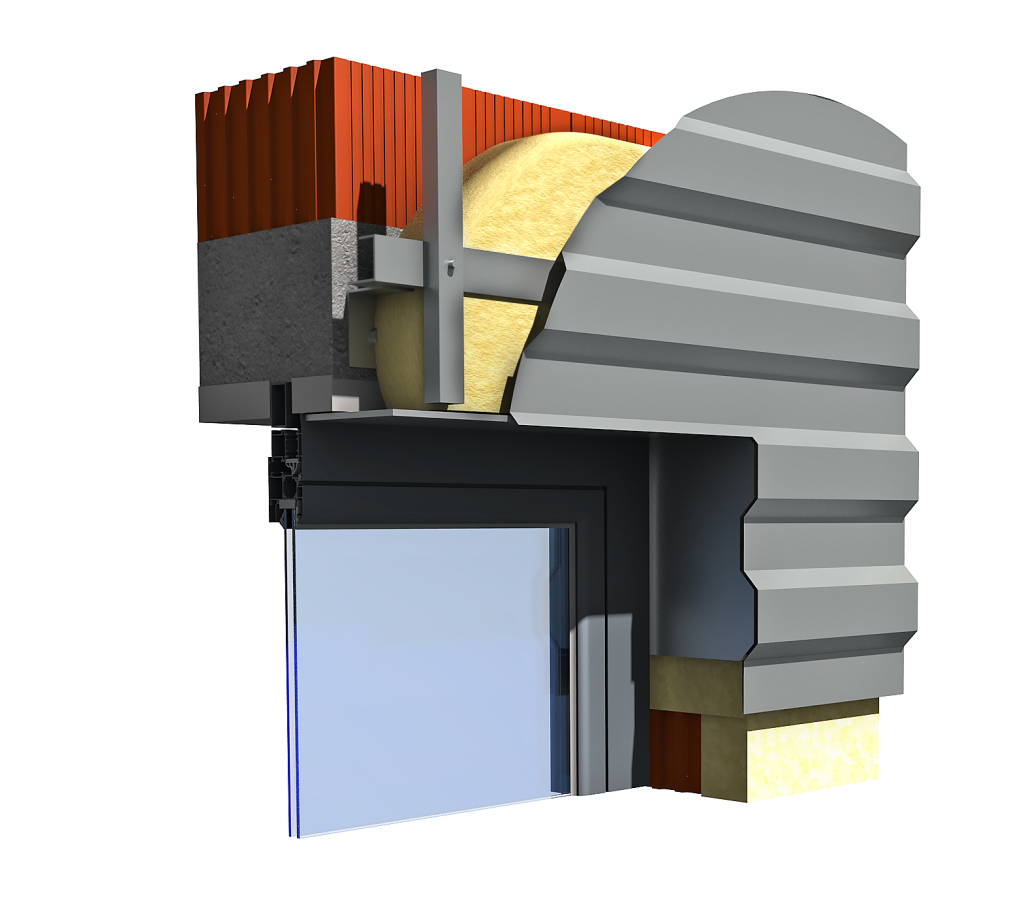

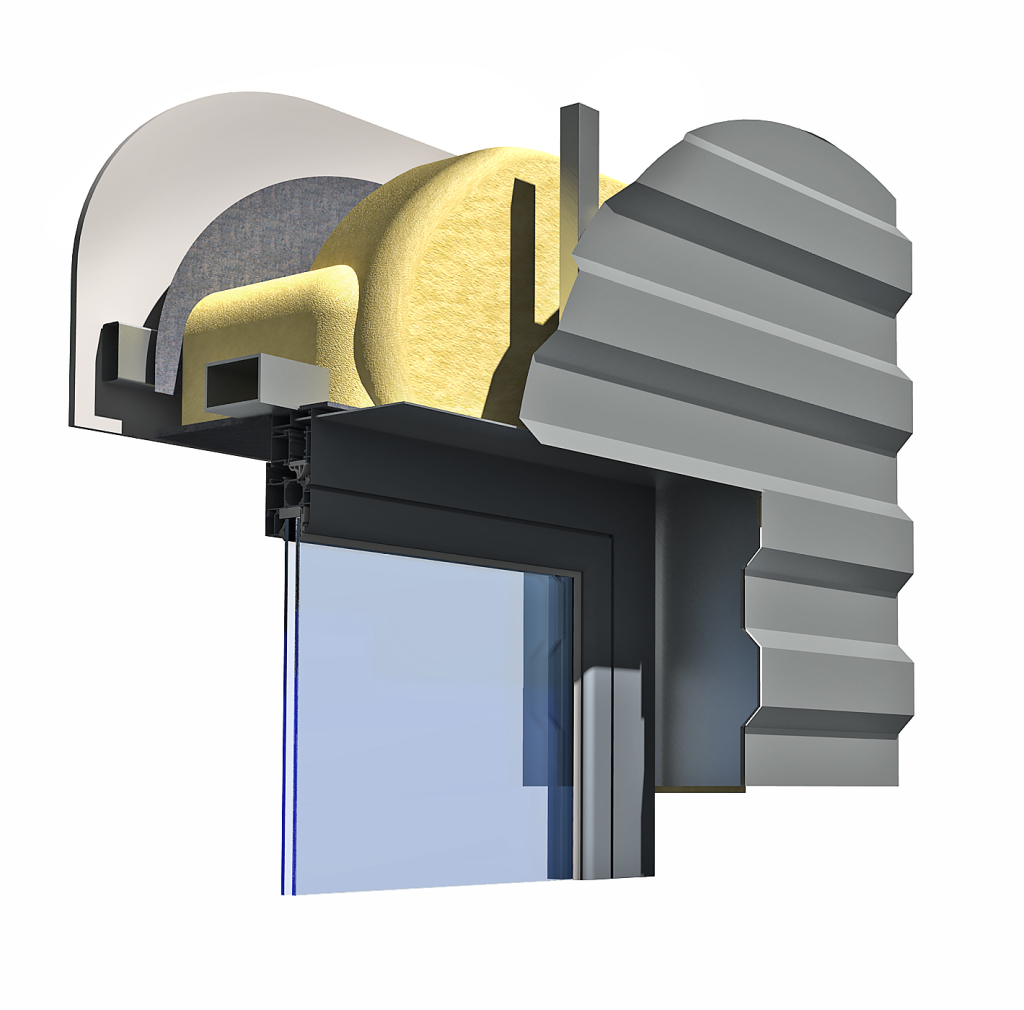

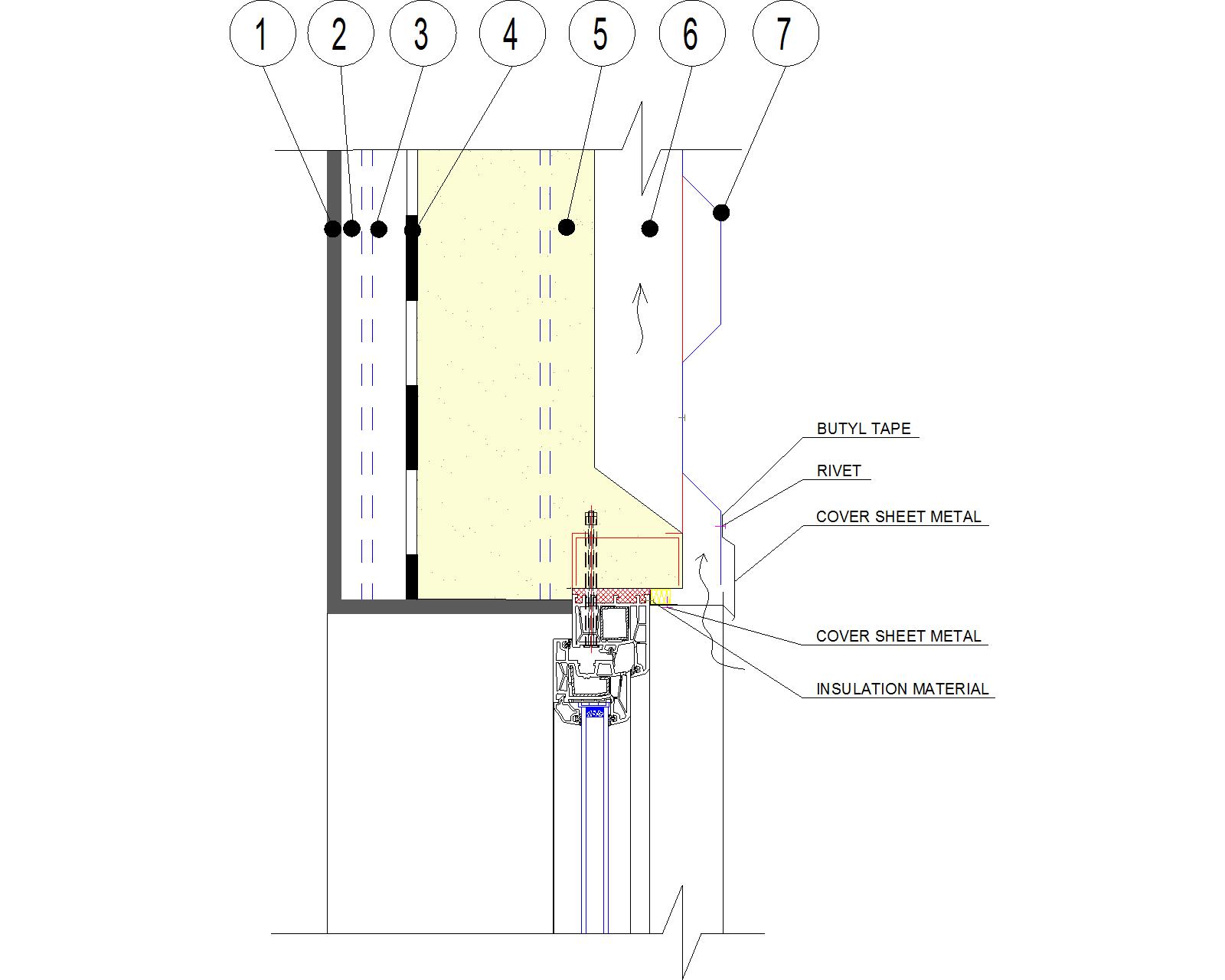

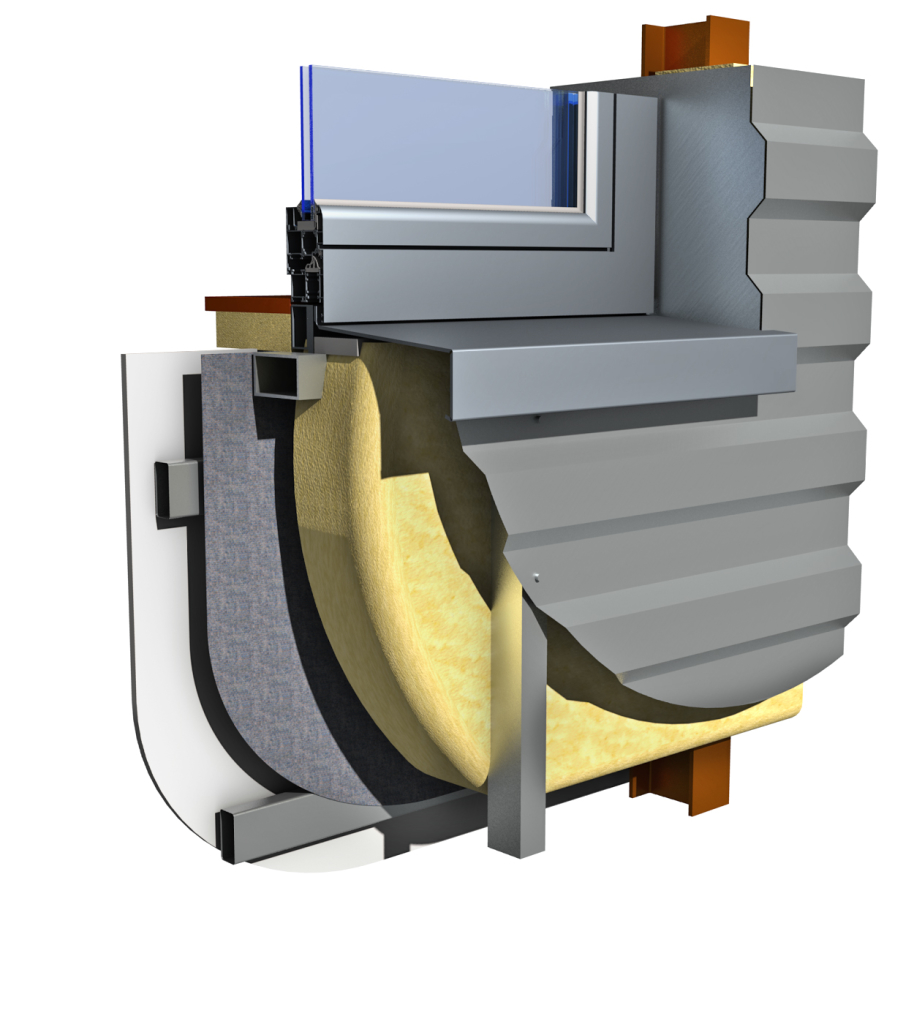

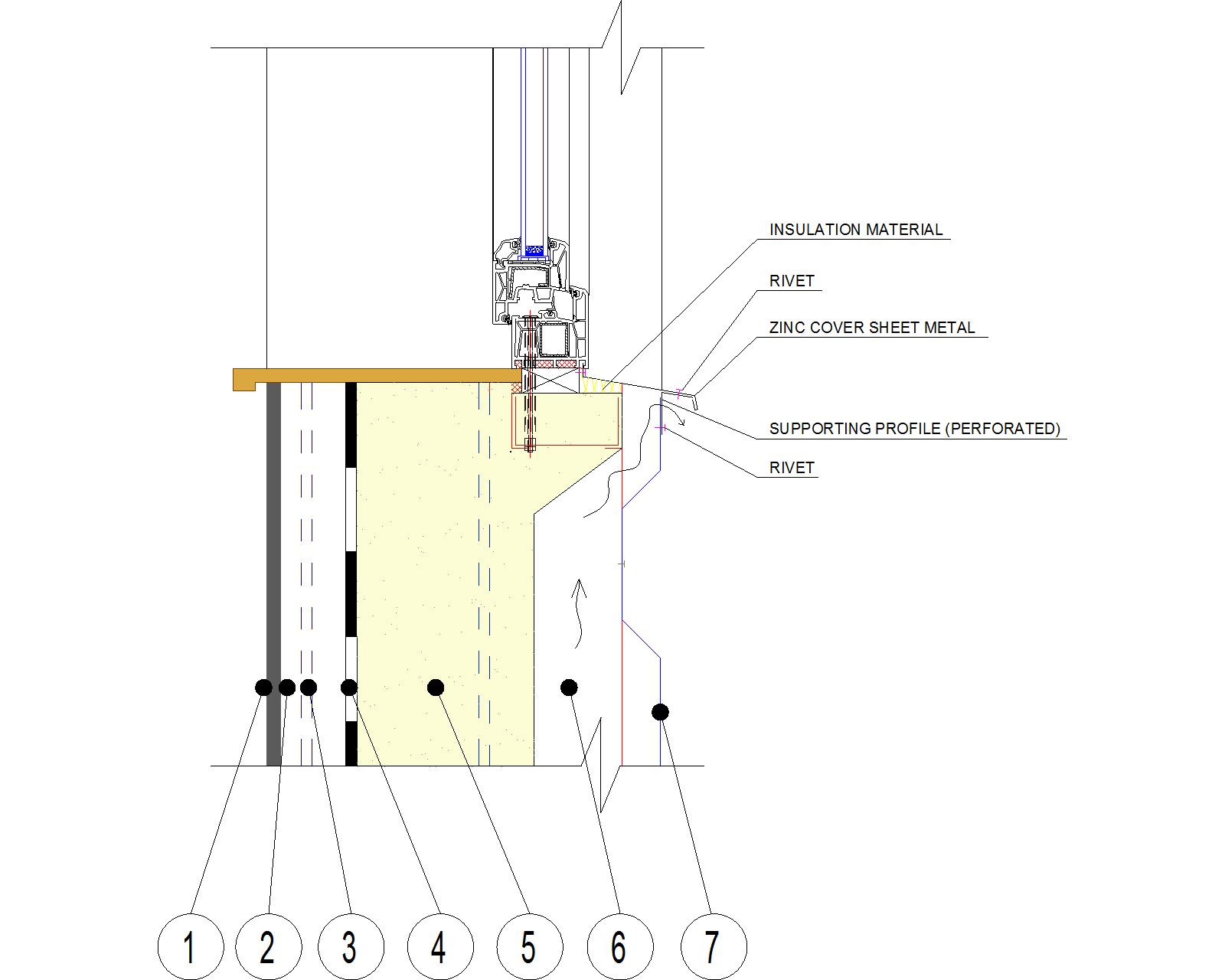

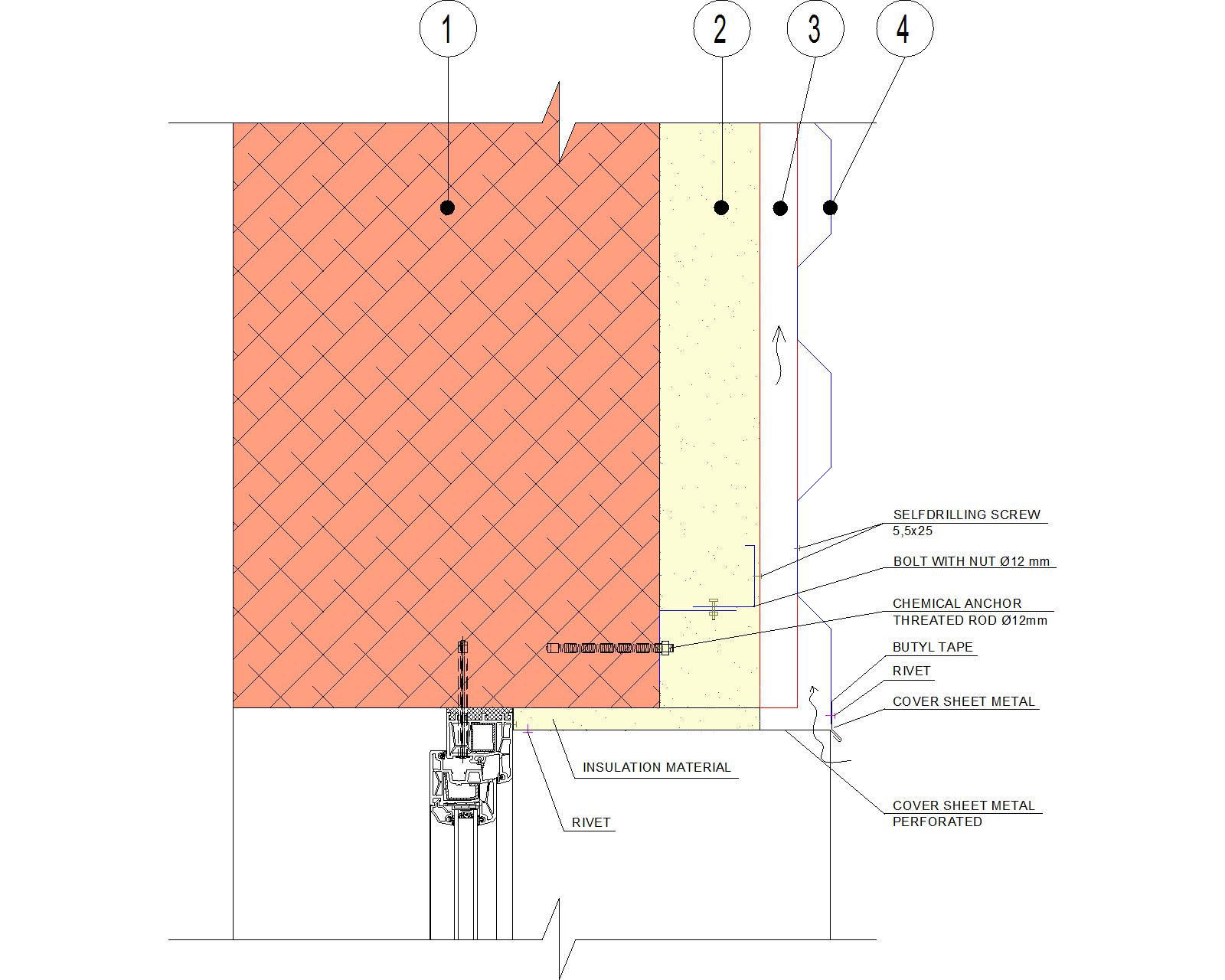

PLASTIC WINDOW HEAD INSULATION

Structure characteristicts:

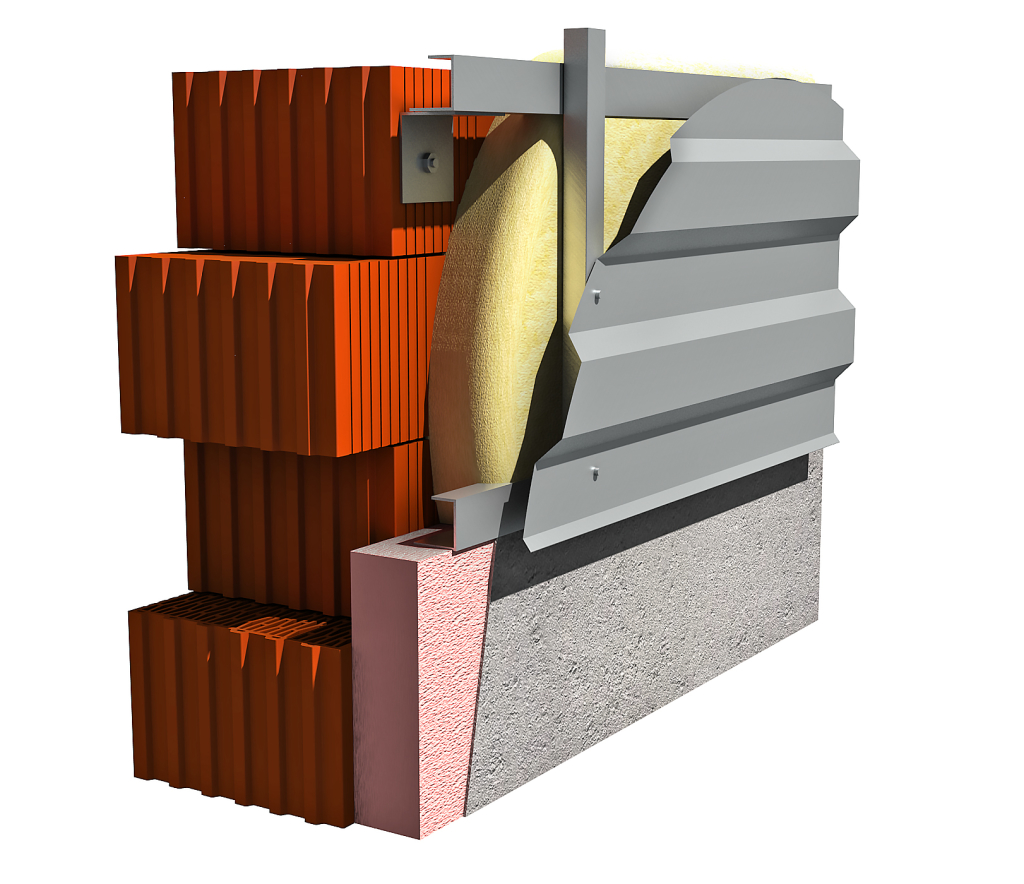

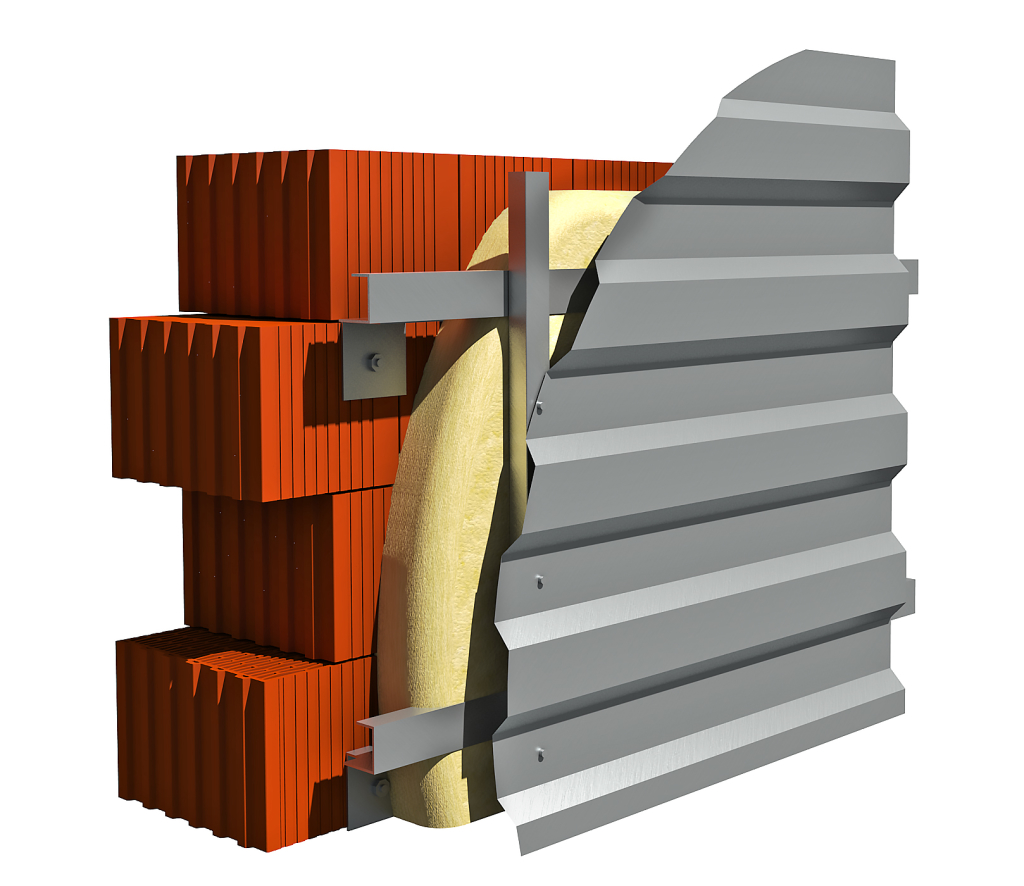

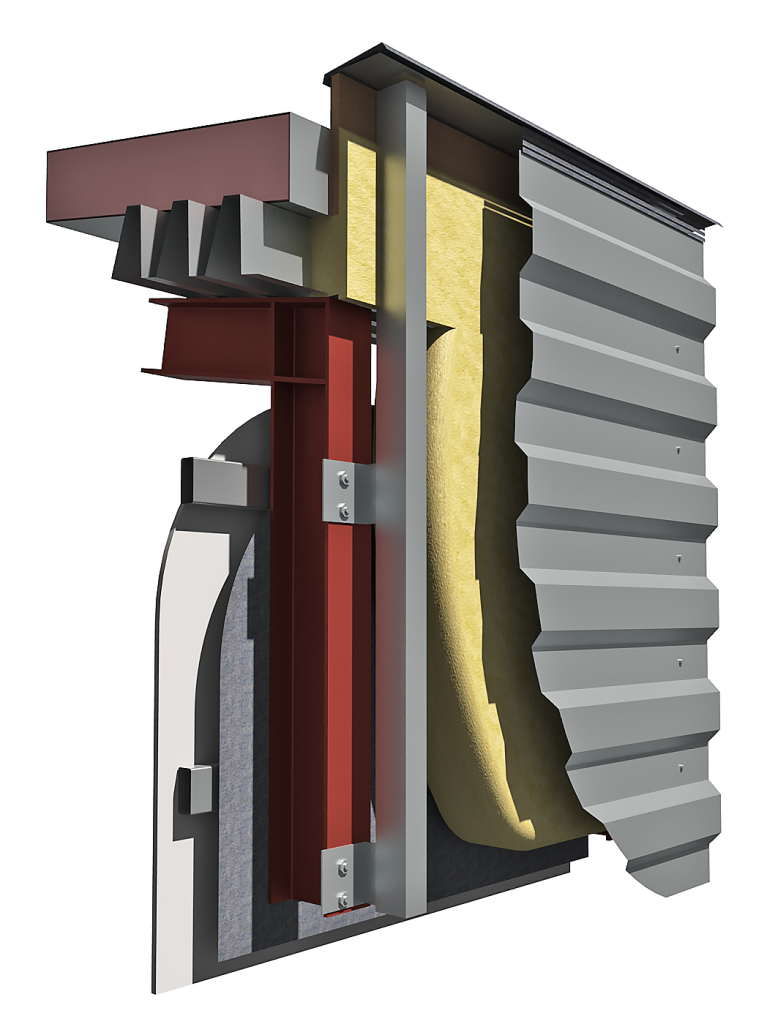

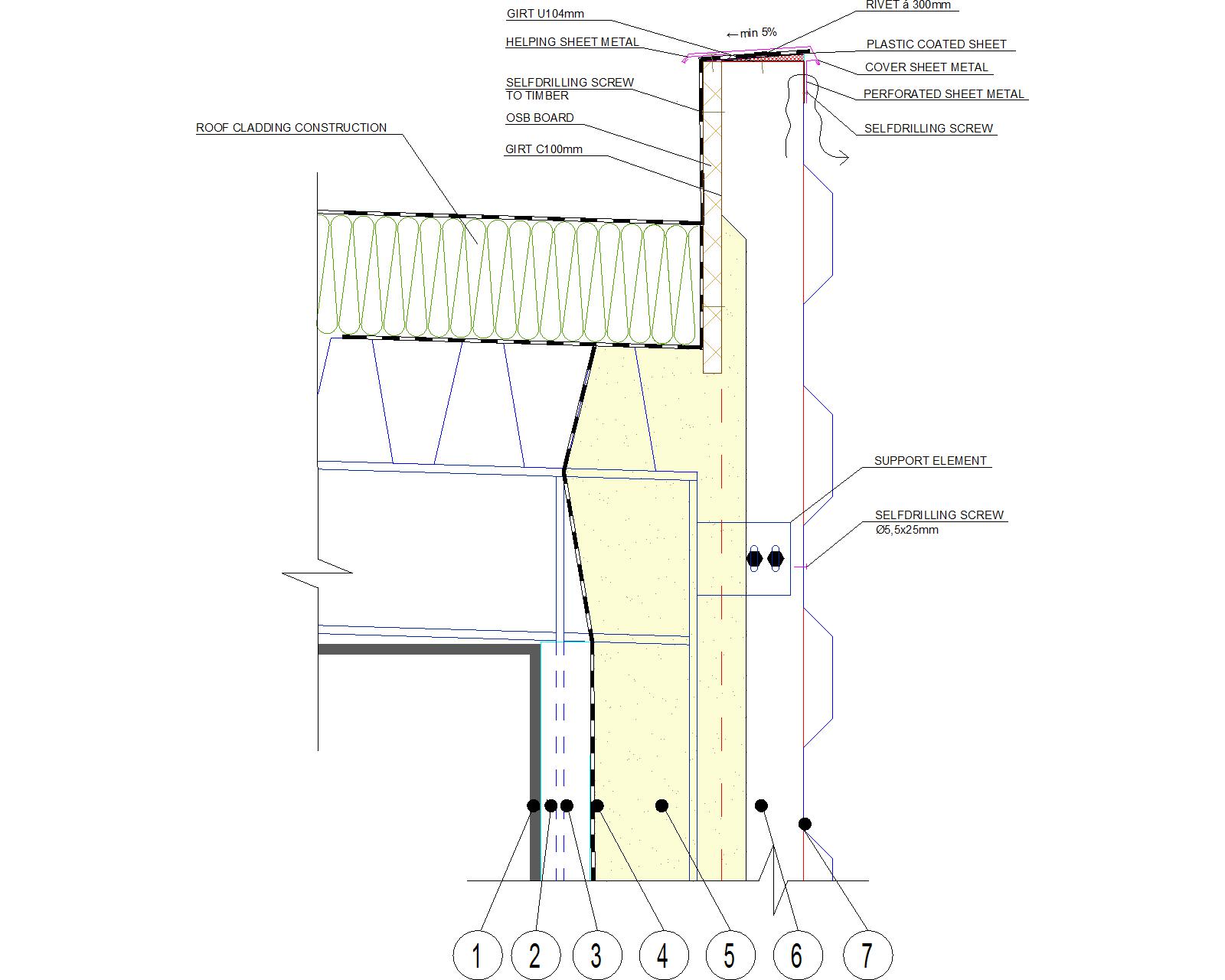

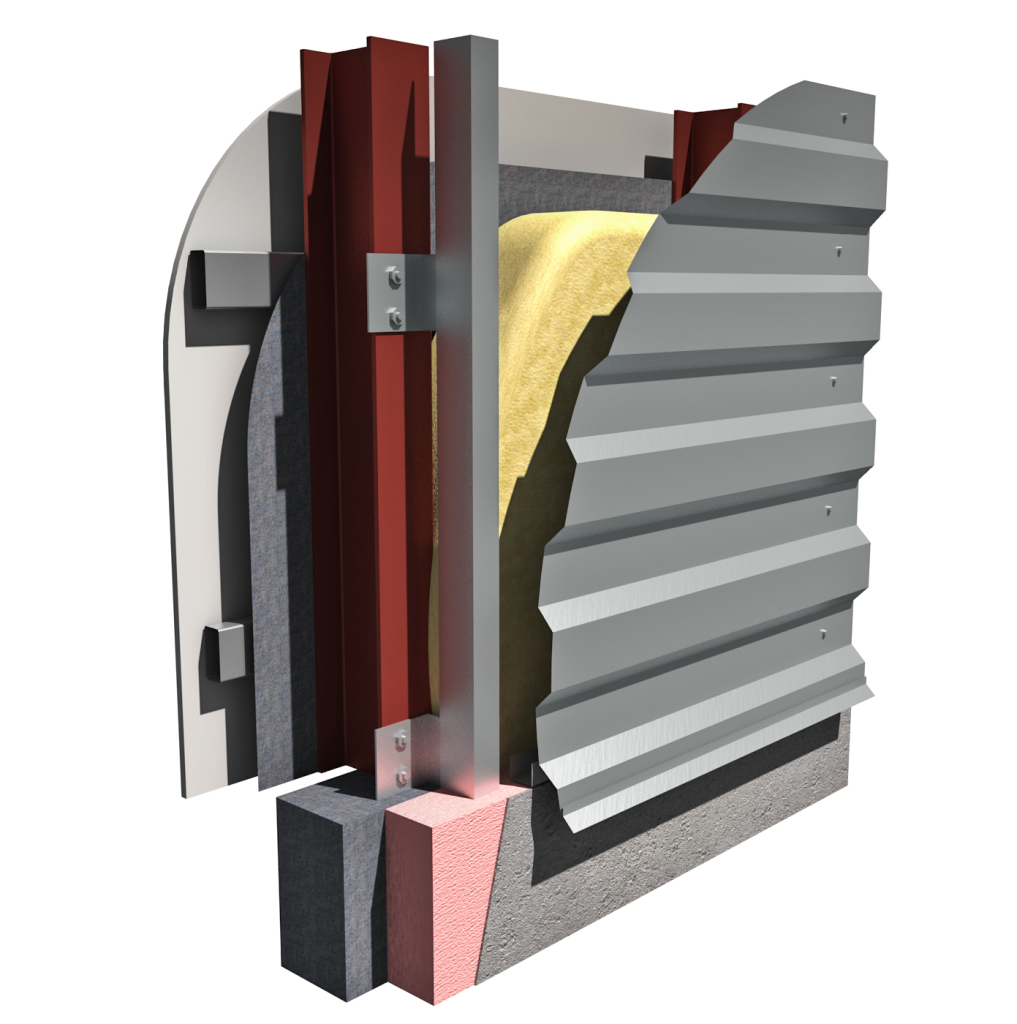

EXISTING WALL DONE FROM BRICKS, INSULATED WITH THERMAL INSULATION ICYNENE TO BEARING STRUCTURE OF EXTERNAL FINISHING. VENTED AIRSPACE IS CREATED BY SUPPORTING STRUCTURES AND EXTERNAL FINISHING LAYER IS FIXED / GLUED TO THEM.

Structure advantages:

| THERMAL TRANSMITTANCE VALUE ACCORDING TO CSN 730540 | |||

|---|---|---|---|

| REQUIRED THERMAL TRANSMITTANCE VALUE U [W/m2K] | 0.3 | ||

| CALCULATED THERMAL TRANSMITTANCE VALUE U [W/m2K] | 0.29 | ||

| ICYNENE H2FOAM LITE (LDC-50) | 0.38 | ||

| ICYNENE H2FOAM LITE PLUS (LDC-70) | 0.36 | ||

| ICYNENE H2FOAM FORTE (MDR-210) | 0.32 | ||

| TECHNICAL PARAMETERS OF STRUCTURE | |||

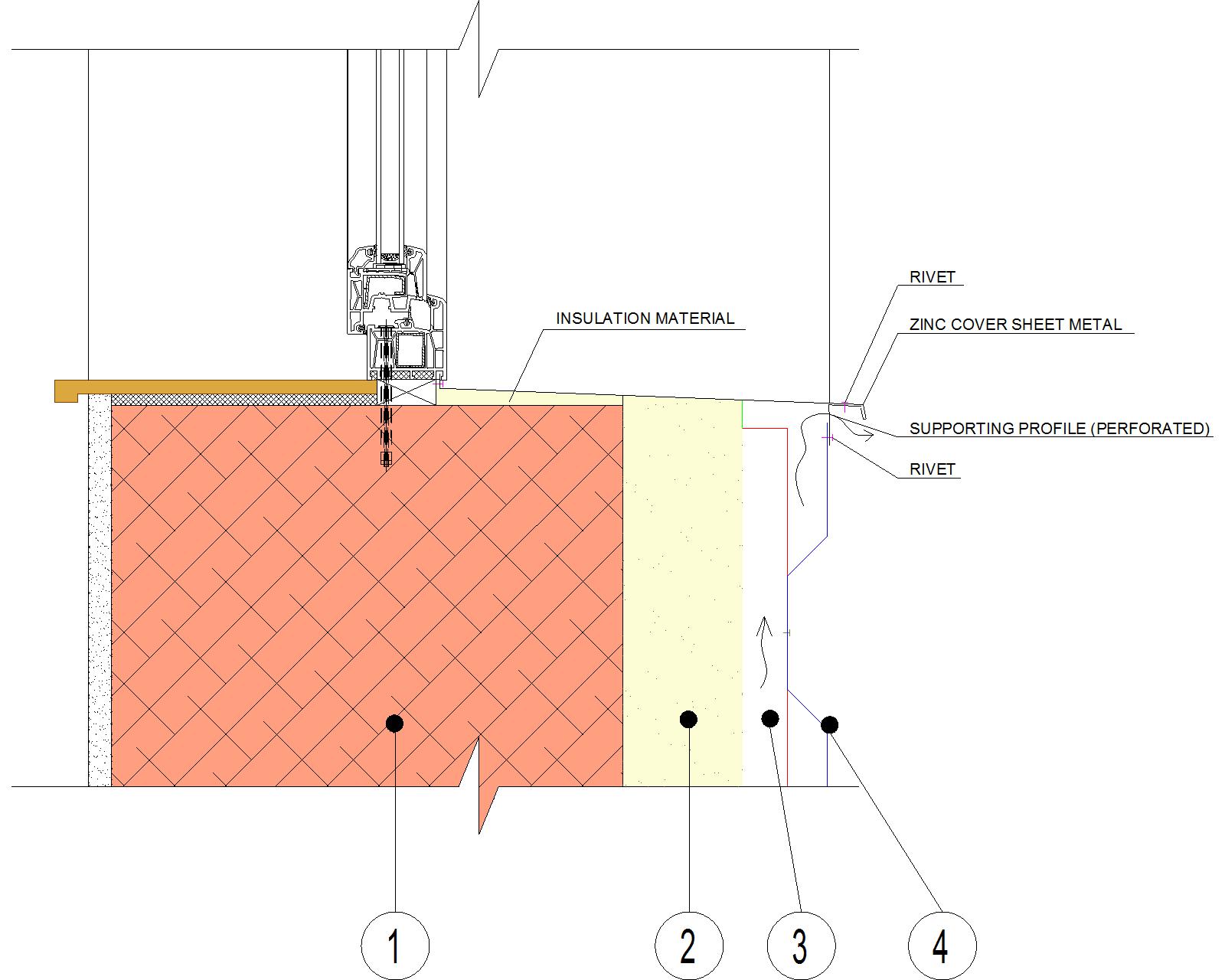

| LABEL | LAYER | THK. [mm] | DESCRIPTION |

| 1 | BRICKS / POROTHERM / HELUZ / YTONG | 450 | EXISTING BEARING STRUCTURE |

| 2 | TI ICYNENE - SUPPORTING PROFILES FROM AL, ZINC STEEL, WOOD | 100 | THERMAL INSULATION LAYER - BEARING STRUCTURE OF EXTERNAL FINISHING |

| 3 | AIRSPACE WITH ALLUMINIUM - ZINC Z PROFILE | 40 | VENTED AIRSPACE - SUPPORTING STRUCTURE OF EXTERNAL FINISHING |

| 4 | METAL SHEET / FUNDERMAX / CETRIS / CEMBONIT / NOVABRIK / KRONOPLAN | 8-35 | EXTERNAL FINISHING |